Machining:

Precision & Performance for Your Prototypes & Series Production

Machining, also known as subtractive manufacturing, is an industrial technology recognized for its exceptional precision and material versatility. Unlike additive manufacturing, it shapes parts by removing material, making it ideal for prototyping and small to medium production runs.

At MMB VOLUM-e, we specialize in the creation and refinement of both small and large-scale parts, ensuring they meet their final geometrical and technical specifications.

High-Precision Subtractive Manufacturing: From One-Off Parts to Series Production

Every project starts with an in-depth technical study (CAD models, drawings, CAM programming) to ensure dimensional accuracy, material integrity, and shape precision.

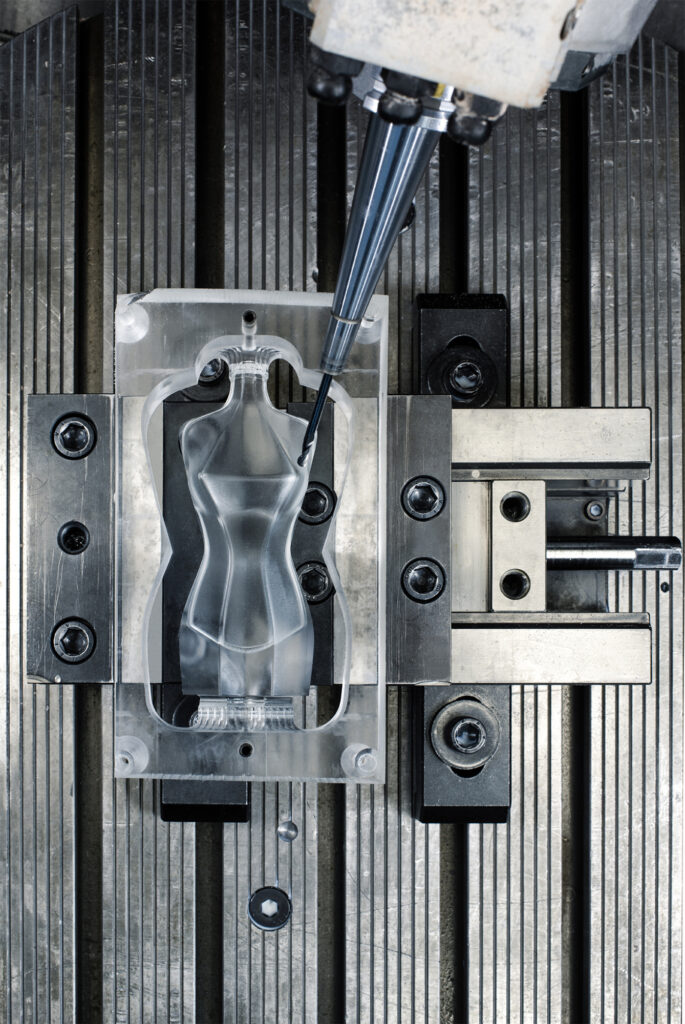

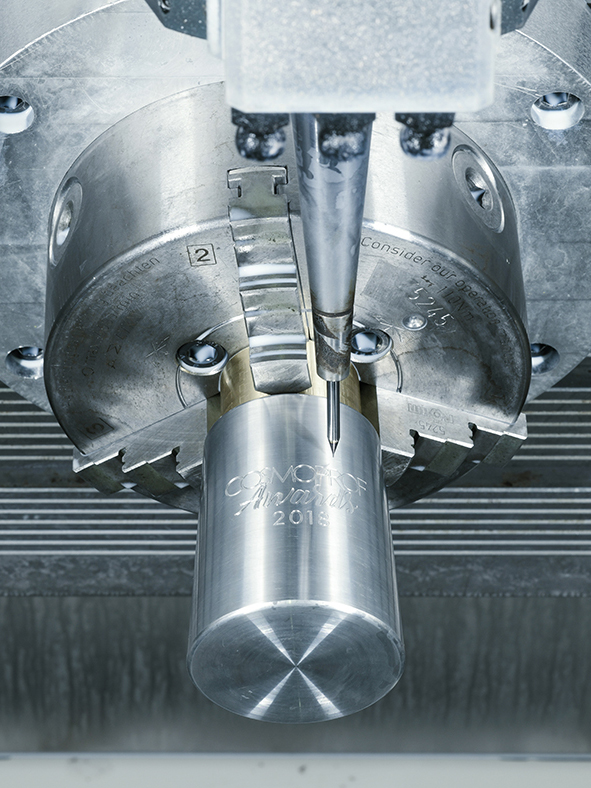

Our machining capabilities allow us to manufacture complex geometries directly from solid material blocks, refine raw parts from stereolithography, vacuum casting, or metal additive manufacturing and engrave pre-painted, semi-finished, or fully finished parts for a fully customized result

After machining, parts can undergo high-end finishing processes such as cabinet painting, metallization, or chroming, combining high precision with luxury-grade aesthetics.

The MMB VOLUM-e Advantage:

- Diverse Material Expertise: We specialize in machining both soft and hard materials, including LAB, foam, Plexiglas, aluminum, brass, and wood

- Large-Format Machining: We handle large-scale projects with machining capacities up to 4500 × 1800 × 1400 mm for soft materials.

- Advanced Hard Metal Refinement: Our expertise includes high-precision finishing for raw hard-metal parts produced through additive manufacturing.

- Agility & Rapid Turnaround: A diverse machine fleet allows us to deliver short lead times and effectively tackle even the most complex projects.

Prototype & Large-Scale Machining for Your Production Needs

Our Machining Capabilities Include:

- 7 machining centers (3- and 5-axis), designed for both soft and hard materials

- Large-scale capacity: up to 4500 × 1800 × 1400 mm for soft materials

- Tool measurement room (pre-setting bench)

- Tool preparation room (shrink-fit tool bench)

Types of Machined Parts:

- Solid block machining: LAB, foams, Plexiglas, aluminum, brass, wood, and more

- Refinement of raw parts from stereolithography, vacuum casting, or metal additive manufacturing

- Engraving of pre-painted finished parts