In the world of luxury, seamlessly combining performance and aesthetics is essential. Selective Laser Sintering (SLS), an advanced 3D printing technology, offers exceptional design freedom for high-end functional objects. By using a laser beam to selectively fuse thermoplastic powders layer by layer, this process enables the creation of solid, precise, and intricately detailed pieces.

Why Choose Powder Sintering for the Luxury Industry?

- Strength & Elegance – The materials used in SLS offer exceptional mechanical and thermal properties while ensuring a refined aesthetic, making them ideal for high-end functional pieces.

- Durability & Reliability – This technique provides outstanding resistance to shocks, water, and temperature variations, ensuring the longevity of each creation.

- Material Diversity – A wide range of powders allows for varied textures and properties, from rigid plastics to flexible materials, including advanced solutions such as aluminum-filled or flame-retardant PA.

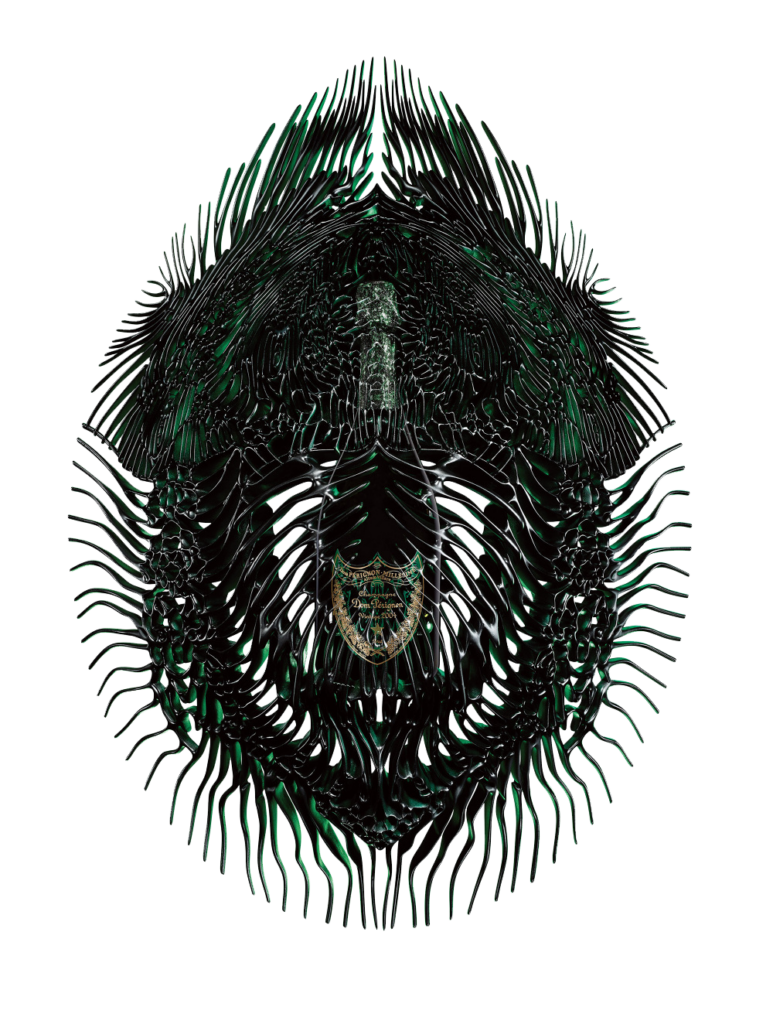

- Complexity & Customization – Powder sintering enables the creation of intricate designs with no shape limitations, perfectly suited to the craftsmanship and bespoke requirements of the luxury sector.

An Ideal Process for Innovation and Bespoke Production

Selective Laser Sintering (SLS) is a key solution for rapid prototyping and the production of small to medium series of high-performance parts. It meets the demands of luxury brands seeking to combine innovation, customization, and impeccable quality.